See It in Action at Your Factory

Book a free on-site demo and watch the KHD Static Spinner deep-clean your conveyor belts using powerful dry vapour steam.

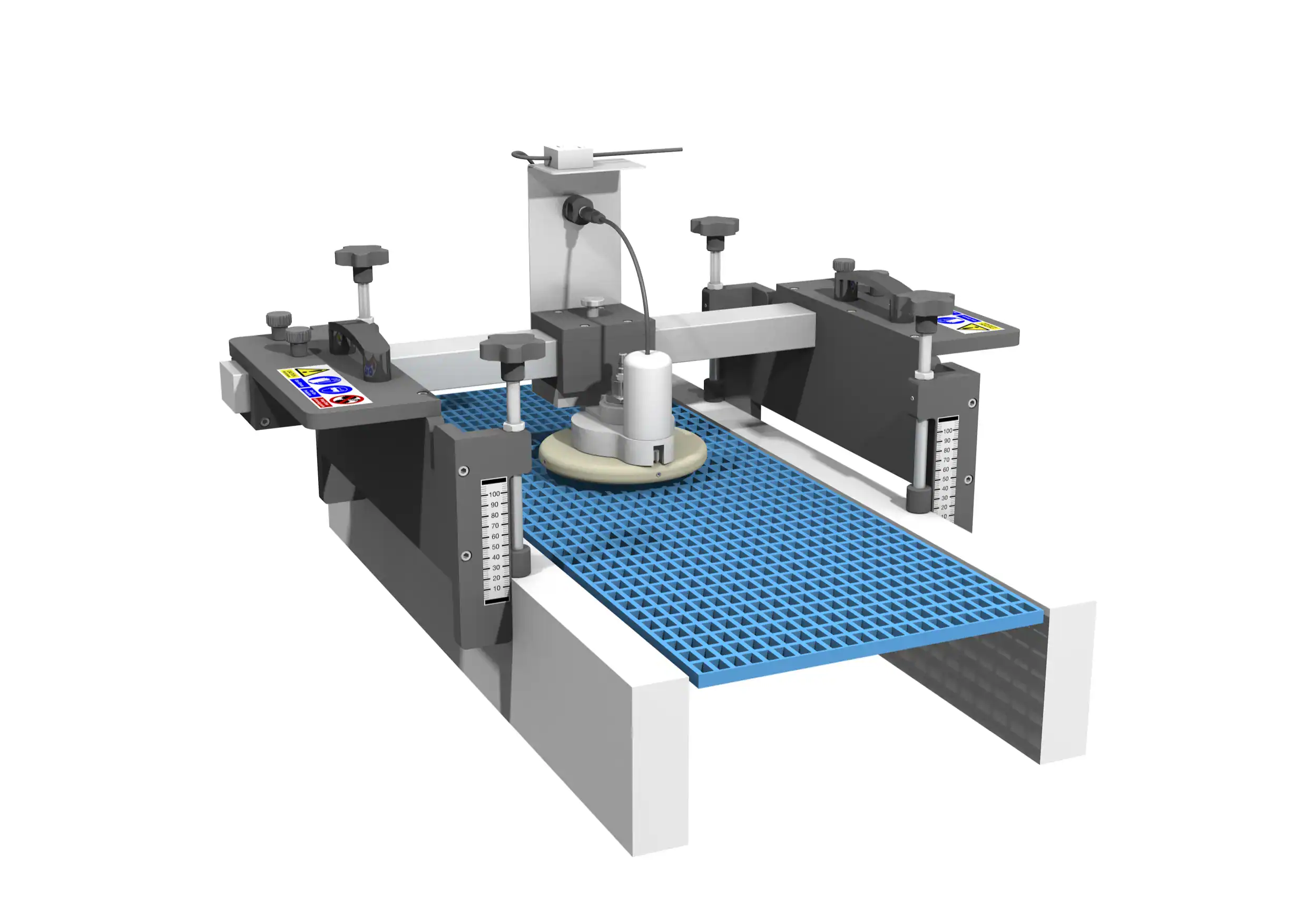

Book a DemoThe KHD Static Spinner is a powerful portable dry-steam cleaning system for modular mesh and spiral conveyor belts. Designed to move easily between production lines, it provides hygienic, chemical-free cleaning using powerful dry vapour steam — removing grease, oils and residues while using less than 25 litres of tap water per hour.

Simply move the head into position and let it work away. It’s semi-automated — you guide it, it does the hard part. But if “semi-automated” doesn’t sound automated enough, we get it. Check out our Jet System 5, the best-selling fully automated modular conveyor cleaning system from KHD.

The KHD Static Spinner is the perfect balance between handheld and fully automated cleaning systems — a portable, semi-automated conveyor belt cleaning solution for bakeries and food factories. Using dry vapour steam, it removes stubborn contamination from modular mesh, spiral and wire belts without the need for chemicals or excess water.

Built for flexibility, the Static Spinner can be moved quickly between different belt lines, allowing one operator to deep-clean multiple conveyors with minimal downtime. The unit connects directly to KHD’s industrial steam generators, delivering consistent steam pressure for powerful, hygienic cleaning at source.

This system is ideal for facilities wanting to improve hygiene standards, reduce manual labour, and minimise water use while maintaining complete control over where and when belts are cleaned.

By targeting specific sections of belt runs, the KHD Static Spinner helps eliminate grease, oils, coatings, flour, dairy residues, chocolate, fruit juice deposits and sticky drink residues, restoring belts to a food-safe condition quickly and effectively.

Whether you operate spiral coolers, mesh conveyors, oven in-feeds, or modular plastic belts, the KHD Static Spinner offers portable, food-safe efficiency — providing the advantages of automated cleaning without the need for a fixed installation.

Book a free on-site demo and watch the KHD Static Spinner deep-clean your conveyor belts using powerful dry vapour steam.

Book a Demo